Are you searching for that extra edge at your next track day with your Yamaha R3? When pushing your lightweight sportbike to its limits, every component matters—especially your brakes. Ceramic brake pads have become a hot topic among performance riders, but do they actually deliver an advantage for R3 track applications?

Let’s dive into the real-world pros and cons of ceramic brake pads for your Yamaha R3 track day weapon.

What exactly are ceramic brake pads?

Ceramic brake pads use a ceramic matrix combined with copper fibers and binding resins. These pads typically contain up to 50% copper content to help with heat dissipation, as noted in an informative video on brake pad composition. This material composition gives them distinctive performance characteristics that differ significantly from the stock or aftermarket sintered metallic options.

Unlike sintered pads, which contain 30-70% metal content (primarily copper alloy), ceramics offer a different balance of properties that can affect your braking experience on track.

Performance advantages for R3 track riders

Initial bite and modulation

Ceramic pads offer excellent initial bite without being too grabby—a critical factor when trail-braking into Turn 1 at your local track. The predictable engagement point allows for precise modulation, giving you confidence to brake later while maintaining control.

This consistent feel throughout the lever travel can be particularly valuable on the lightweight R3, where brake control is essential for maintaining corner speed and racing lines.

Heat management

When you’re repeatedly hammering the brakes from 100+ mph into tight hairpins, heat buildup becomes a major concern. Ceramic pads excel at dissipating heat through their copper fiber content, helping prevent brake fade during extended sessions. According to JHP’s material comparison, while sintered pads can handle temperatures up to 900°C, ceramics still offer excellent heat resistance suitable for most track conditions.

For R3 riders who might not generate the extreme temperatures of heavier bikes but still need consistent performance lap after lap, the heat management characteristics of ceramics strike a practical balance.

Low dust and noise

After a full day at the track, you’ll notice significantly less brake dust with ceramic pads compared to sintered options. This means less cleanup and maintenance between sessions. They also tend to run quieter—though this is less relevant in the track environment where performance takes priority over comfort.

The reduced dust can be a welcome benefit when maintaining your track bike between race weekends or track days.

Performance drawbacks to consider

Initial cold performance

One notable drawback of ceramic pads is their need for proper warm-up. Your first lap out of the pits might feel a bit sketchy until the pads reach optimal operating temperature. This contrasts with sintered pads, which offer better initial performance in cold conditions.

This warm-up requirement means you’ll need to plan your out-lap accordingly and be conscious of brake feel until everything reaches operating temperature.

Wet weather limitations

If you’re planning to track your R3 in mixed weather conditions, be aware that ceramic pads generally don’t perform as well when wet. According to a comprehensive comparison of brake pad types, sintered pads typically provide superior stopping power in wet conditions—something to consider if you frequently encounter rain during track days.

For club racers who compete rain or shine, this limitation could be a decisive factor in your brake pad selection.

Cost considerations

Quality ceramic pads typically come with a higher price tag than stock or basic aftermarket options. While you’ll save some money on less frequent rotor replacements, the initial investment is higher.

The cost-benefit analysis depends on your track frequency and budget—occasional track day enthusiasts might find it harder to justify the premium than dedicated racers who are constantly pushing their equipment to the limits.

Real-world track scenarios

Imagine you’re approaching the high-speed braking zone at the end of a long straight. With ceramic pads:

Your initial brake application provides a progressive, predictable response that allows you to modulate pressure as you transition to trail braking. As you tip into the corner, the consistent feel helps you precisely adjust your line without the grabby characteristics that can unsettle the lightweight R3 chassis.

Midway through a 20-minute session, when other riders might be experiencing brake fade, your ceramics continue delivering reliable performance lap after lap. The heat dissipation properties help maintain consistent lever feel even as temperatures build.

By the end of the day, your rotors show minimal wear patterns and your wheels aren’t caked in brake dust—making post-track maintenance significantly easier.

However, during your morning warm-up session when track temperatures are cooler, you might need an extra lap to get proper brake feel, requiring some patience before pushing hard into braking zones.

Compatibility considerations

For optimal performance with ceramic pads on your R3, consider these complementary upgrades:

- HEL Braided Brake Lines Kit – Improves brake feel and eliminates the spongy response of stock rubber lines

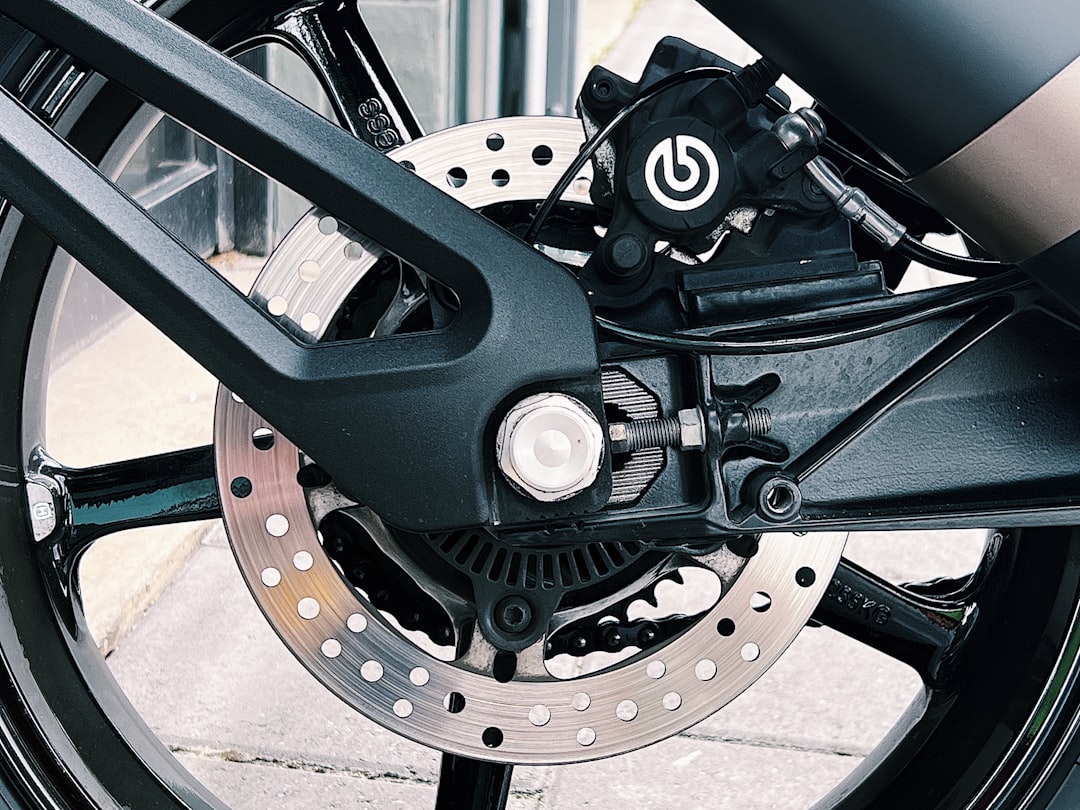

- Brembo T-Drive Brake Disc or Galfer Wave Rotor – Better heat dissipation and improved pad contact

- Ferodo Racing CP1 Brake Pads – High-performance option worth considering

These upgrades work together as a system, with each component enhancing the overall braking performance of your R3 on track.

The bottom line: Are ceramics right for your R3?

Ceramic brake pads make the most sense for R3 track riders who:

- Prioritize consistent braking feel and modulation

- Value reduced maintenance (less dust, longer rotor life)

- Ride primarily in dry conditions

- Are willing to properly warm up their brakes before pushing hard

However, stick with sintered/metallic pads if you:

- Need immediate braking performance from cold

- Frequently ride in wet conditions

- Prioritize absolute maximum stopping power over feel

- Are on a tighter budget

Remember that optimal braking isn’t just about pads—it’s about the complete package. Your tire choice significantly impacts braking performance, so consider pairing your brake upgrades with quality rubber like Michelin Power Cup 2 or Pirelli Diablo Superbike Slicks.

And don’t forget—all that stopping power needs to be balanced with your drivetrain setup. A properly maintained chain like the DID 520 ZVMX ensures reliable power delivery when exiting those corners you just expertly trail-braked into.

The ceramic versus sintered decision ultimately comes down to your riding style, track conditions, and performance priorities. For many R3 track enthusiasts, the balanced characteristics of ceramic pads provide a performance advantage that justifies the investment, particularly if you value consistent feel and modulation over absolute maximum stopping power.